Raiko Premium

RAIKO® Premium gutters are made of the highest quality Swedish SSAB coated steel, which makes them more durable, more resistant to scratches and various weather conditions. The multi-layer GreenCoat® RWS coating guarantees excellent corrosion resistance of the components, which extends the service life of the system.

We provide a 30-year warranty for the RAIKO® Premium system.

Simple and easy assembly. No permanent connections with rivets or screws. RAIKO® systems are one of the easiest to install gutter systems on the market.

Installation and any repairs or maintenance can be done without the help of roofing teams and specialized tools.

The RAIKO® Premium system is 100% complete and fully compatible with Scandinavian gutter systems.

In the event of replacing any system components, the customer can purchase RAIKO® products and connect them with his existing gutter system, which is already installed on his roof.

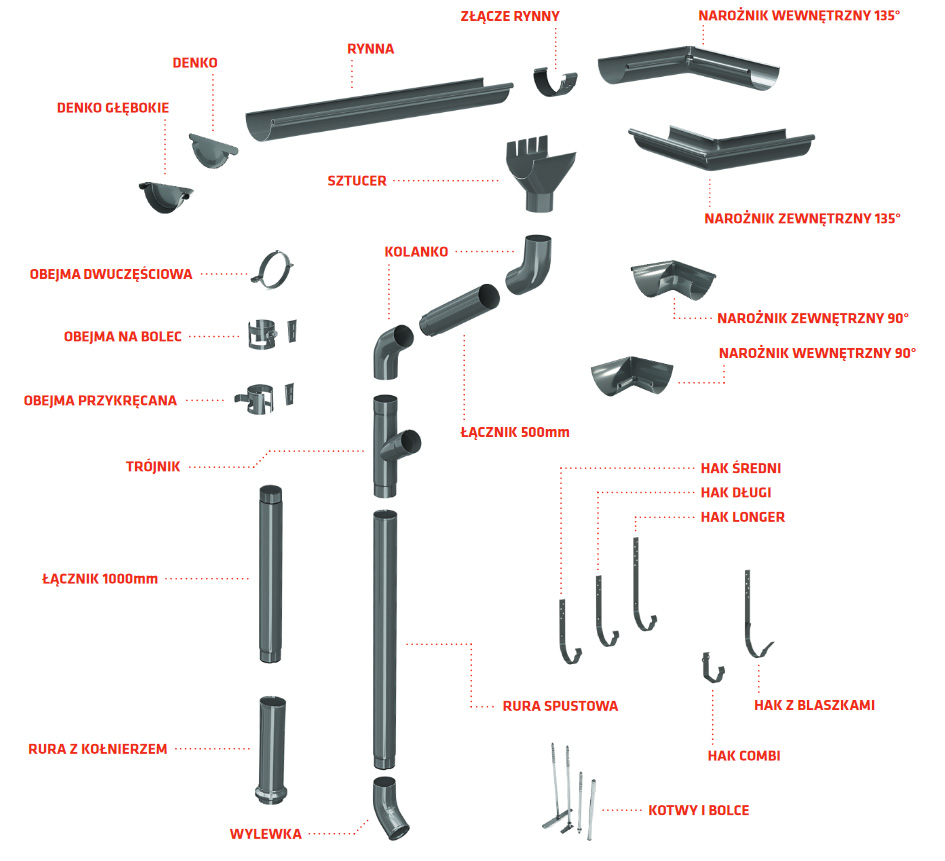

The RAIKO® Premium gutter system is a complete drainage system ideal for any roof, characterized by durability, ease of installation, as well as completeness and compatibility. Each element of the RAIKO® Premium gutter system is the result of the selection of optimal technological solutions, the uniqueness of which is protected by patents.

Thanks to their special features, the gutters in the RAIKO® Premium system have excellent corrosion protection, are very easy to install, maintain and serve several times longer than other gutter systems.

We provide a 30-year warranty for the RAIKO® Premium system.

Raw material

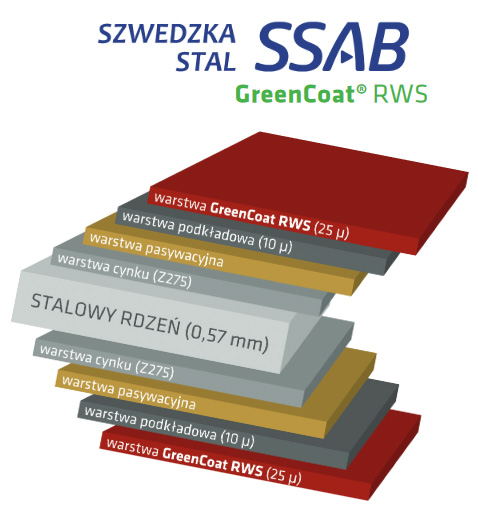

The RAIKO® Premium gutter system is based on the most modern Swedish cold pressing technology. The system components are made of the highest quality steel sheet (0.6 mm), galvanized on both sides (275 g / m)2), constituting a thick core, covered on both sides with a strong layer of paint with a thickness of 35 microns (GreenCoat® RWS coating). The steel from which the RAIKO® Premium system is produced is manufactured by the Swedish steelworks SSAB.

The GreenCoat® RWS coating, thanks to fine polymer grains in the external paint layer, is characterized by a very high surface smoothness, color stability and resistance to scratching and all weather conditions. Eight protective layers covering the sheet metal (four on each side) guarantee excellent corrosion resistance of the elements, which significantly extends the service life of the system. This coating is resistant to aggressive chemical components dissolved in rainwater and air pollution. As a result, the coating retains its structure, original color and gloss over time.

| PARAMETR | WARTOŚĆ | NORMA |

|---|---|---|

| ZASTOSOWANIE | na zewnątrz | EN 10169+A1 |

| GRUBOŚĆ POWŁOKI | 35 μm / 35 μm | ISO 2808 |

| TOLERANCJA GRUBOŚCI POWŁOKI | 6 μm (średnia 3 pomiarów) | EN 10 169-1 |

| POŁYSK | 40 | EN 13523-2 |

| MIN. PROMIEŃ GIĘCIA | 1T (ciemne) - 2T (jasne) | EN 13523-7 |

| MIN. TEMP. FORMOWANIA | +15°C | *** |

| ODPORNOŚĆ NA UDERZENIA | 8 | EN 13523-5 |

| TWARDOŚĆ | HB-F | EN 10 169-1 |

| MAX. TEMPERATURA PRACY | +100°C | *** |

| KATEGORIA UV | Ruv3 | prEN 10169-2 |

| ODPORNOŚĆ NA KOROZJĘ | RC5 | EN 10 169-1 |

| ODCHYŁKA KOLORÓW | E<1.0 | *** |

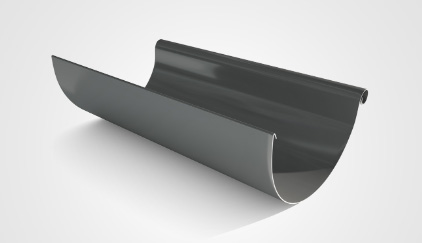

RAIKO gutter system®Premium is available in three sizes and in eleven color variants.

All 100mm / 75mm colors are available on request. Extended lead time.

Your observations regarding the use of the RAIKO gutter system are extremely important to us Raiko® Premium. All comments are carefully analyzed by us and allow us to set new directions for product development. Please report any suggestions directly to the representatives or by e-mail: info@raiko.com

As part of the project RAIKO® Oxygen Partner for our distributors and contractors, we also create special partner and loyalty programs, organize trainings, competitions and other permanent and occasional marketing projects that constitute additional value for our cooperation. Details at our representatives and on the website www.raiko.com

RAIKO system Raiko® Premium as well as other RAIKO systems® are one of the easiest gutter systems on the market to install. No permanent connections with rivets or screws. Installation and any repairs or maintenance can be done without the help of roofing teams and specialized tools.

Proper installation of the system guarantees quick and reliable drainage of water from the roof slopes throughout its lifetime and reduces maintenance only to cleaning the gutters of leaves.

In order to guarantee you full satisfaction with our product, we present installation tips and advice, which can be found on our website and in the published instructional materials. We also organize training for our partners and contractors (roofers). Please read the instructions carefully before installation.

| TABELA WYDAJNOŚCI SYSTEMU ORYNNOWANIA RAIKO | ||

|---|---|---|

| SYSTEM ORYNNOWANIA | POWIERZCHNIA DACHU | |

| 1 SPUST | 2 SPUSTY | |

| 100 mm / 75 mm | > 50 m2 | 50 m2 - 100 m2 |

| 125 mm / 90 mm | 50 m2 - 100 m2 | 100 m2 - 150 m2 |

| 150 mm / 100 mm | 100 m2 - 150 m2 | 150 m2 - 200 m2 |

- Make sure you have all the necessary system components in sufficient quantities.

- Make sure the gutter is slightly lower than the roof extension line so as not to support the sliding snow.

- The gutter should protrude beyond the edge of the roof slope at least half of its diameter.

- Keep the gutter slope towards the downpipe, min. 3-5 mm / rm.

- Remember that the inner edge of the gutter should be 6-10 mm higher than its outer edge.

- Remember to clean the gutter of cut sheet metal pieces and filings. If left, they rust and discolor.

- Bend the hooks (HKS, HKD, HKL) for installation on rafters or boards until the appropriate slope of the gutter is obtained.

- Combi Hooks (HKC) are used for direct mounting on the dashboard.

- Fasten the hooks at intervals of max. 60 cm, place the extreme hooks approx. 10 cm from the ends of the gutter.

- Be sure to attach the hook to each side of the corner.

- We start the assembly by attaching the extreme hooks, then we thread a chalk line between them to mark the assembly line for the remaining hooks.

- In the case of using two downspouts, attach the hooks from the inside with a slope towards the pipes.

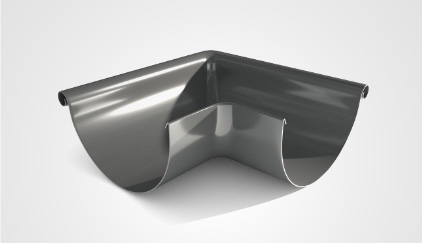

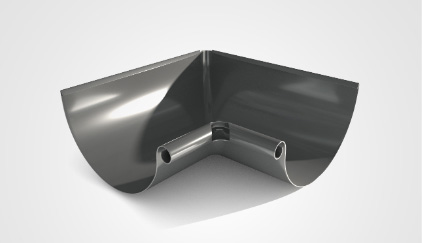

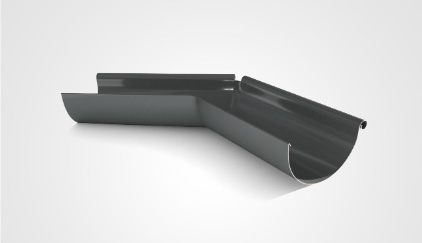

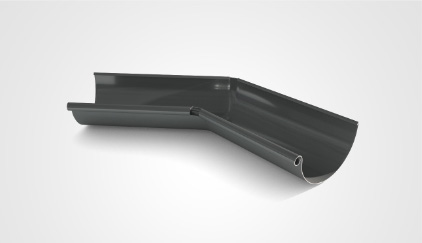

- We embed the gutters (RYN) and corners (NAW, NAZ), starting with the gutter with the cutter mounted.

- Using the gutter joint (ZLR), we seal all connections between gutters and corners. The connections should be at equal distance between the hooks.

- Remember to leave a gap of approx. 5 mm between the gutters to be joined and the corners to compensate for length changes.

- Fasten the buckle on the front part of the joined elements and secure it by bending the plate.

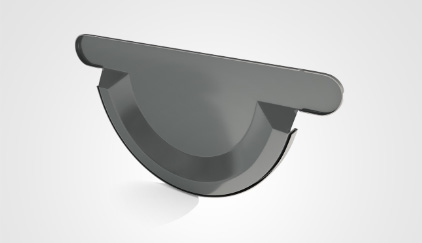

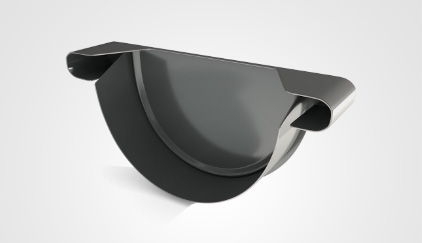

- Finally, fix the bottoms (DEN) at the ends of the gutter, first applying a small amount of roofing sealant to the recesses. Press the front ear on the gutter eversion, bend the rear ear behind the gutter.

- Determine the place on the gutter where the downpipe will be placed, then use a hacksaw to cut a hole. Do not use an angle grinder for this.

- The edges of the cut are turned outwards to facilitate the drainage of water into the rifle.

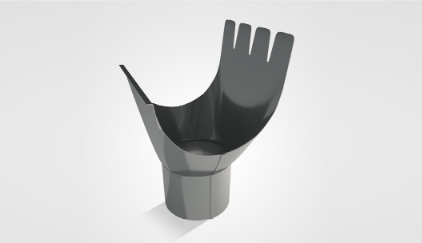

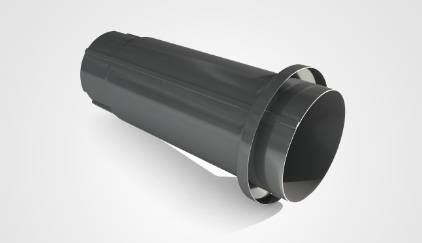

- We install the rifle (PCS) on the gutter, inserting its bent edge into the gutter’s external curvature. Then press it down and bend the mounting flaps inwards.

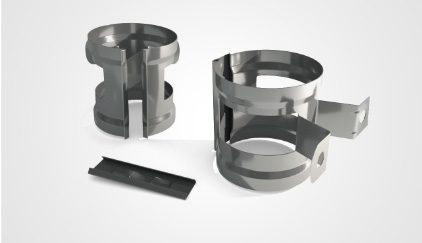

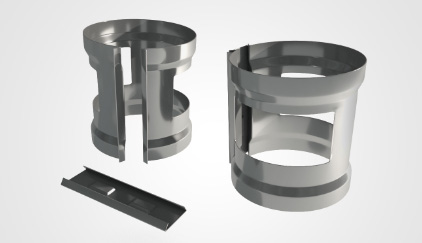

- We mark a line on the wall along which the downspout will run. Then, by applying the pipe clamp (OBP, OBB), mark the place of its fastening and prepare the mounting holes.

- The clamp is mounted with expansion bolts. In the case of mounting to a wall insulated with polystyrene, we use anchors (KTO) or bolts (BDO) of appropriate length.

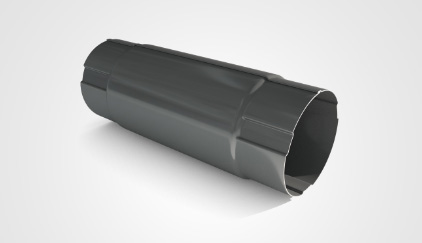

- The first clamp is mounted under the elbow (KOL), and the last one in front of the spout (WYL). The maximum distance between the clamps should not exceed 2 m.

- After fixing the pipes, punch the couplings onto the clamps using a wooden spacer.

- At the end of the downpipe, attach the spout (WYL) or, in the case of drainage to the sewage system, a downpipe with a collar (RSK).

| SIZE | LENGTH |

|---|---|

| 100mm - 125mm - 150mm | 1m - 2m - 4m To order: 3m - 5m - 6m |

| DIAMETER | LENGTH |

|---|---|

| 75mm - 90mm - 100mm | 1m - 3m - 4m To order: 2m - 5m - 6m |

| SIZE | |

|---|---|

| 100mm - 125mm - 150mm |

| SIZE | |

|---|---|

| 100mm - 125mm - 150mm | |

| SIZE | |

|---|---|

| 100mm - 125mm - 150mm |

| SIZE | |

|---|---|

| 125mm - 150mm |

| DIAMETER | LENGTH |

|---|---|

| 75mm - 90mm - 100mm | 0,5m |

| DIAMETER | LENGTH |

|---|---|

| 75mm - 90mm - 100mm | 1m |

| SIZE | |

|---|---|

| 100mm - 125mm - 150mm | Also available with a long arm. |

| SIZE | |

|---|---|

| 100mm - 125mm - 150mm | Also available with a long arm. |

| SIZE | |

|---|---|

| 100mm - 125mm - 150mm |

| SIZE | |

|---|---|

| 100mm - 125mm - 150mm |

| DIAMETER | |

|---|---|

| 75mm - 90mm - 100mm |

| DIAMETER | |

|---|---|

| 75mm - 90mm - 100mm |

| DIAMETER | |

|---|---|

| 75mm - 90mm - 100mm |

| DIAMETER | |

|---|---|

| 75mm - 90mm - 100mm |

| SIZE | LENGTH |

|---|---|

| 100mm - 125mm - 150mm | 175mm - 210mm - 325mm |

| SIZE | LENGTH |

|---|---|

| 100mm - 125mm - 150mm | 70mm - 160mm 210mm - 325mm |

| SIZE | |

|---|---|

| 100mm - 125mm - 150mm |

| SIZE | |

|---|---|

| Bolce: 150mm - 225mm - 300mm | Kotwy: 152mm - 202mm |

| DIAMETER | |

|---|---|

| 75mm - 90mm - 100mm |

| DIAMETER | |

|---|---|

| 75mm - 90mm - 100mm |

| DIAMETER | |

|---|---|

| 75mm - 90mm - 100mm |

Calea Clujului No 81, Turda,

Cluj County. Post code: 401180.

Romania VAT/TAX No:

RO NO 33125302,

PL NIP 5263207250

Tel: 0040364711210

Fax: 0040364711211

Email: info@raiko.com

ul. Radarowa 165

80-298 Gdańsk

Poland

T: +48 58 349 74 91

F: +48 58 341 52 56

Email: info@raiko.com